Uncompromising Multi-Material.

Revolutionize How You Print Your Projects

Vortek Hotend Change System

Why Vortek?

Not A Toy, A Serious Production Powerhouse

Top Tier Printing Performance

Safety, Checked!

Unboxing Video

What's in the box

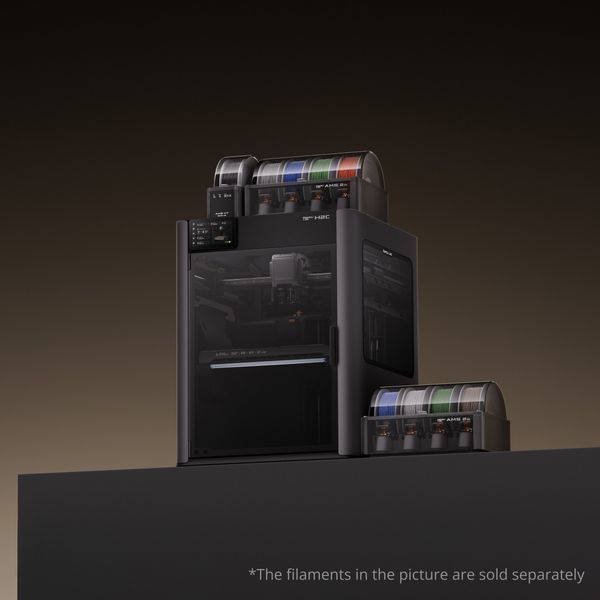

Bambu Lab H2C Laser Full Combo

Product Description

Product Highlights

Fully Automatic Filament Change

Multi-Material Printing with Minimal Purge Waste

Print Durable Joints

Vortek Hotend Change System

Contactless Design For Reliability

Always Delivering the Most Efficient Combination

8-Second Induction Heating

Fully Automatic Nozzle Offset Calibration

Why Choose the Bambu Lab H2C Laser Full Combo?

Minimal Purge Waste Multi-Color Printing--Minimal purge waste multi‑color printing lets the H2C swap colors with far less filament thrown away on wipe or purge towers. The Vortek hotend system assigns each color its own nozzle, so you get vibrant multi‑color parts while saving material and reducing cleanup.

Multi-Material Precision with AMS 2 Pro--The AMS 2 Pro manages up to seven filaments and works together with Vortek to select the best hotend for each material. It enables complex multi‑color and multi‑material parts while keeping extrusion stable and reliable.

10W/40W Laser for Precise Cutting and Engraving--The integrated high‑power laser can cut and engrave a wide range of materials directly in the same machine. You can move from printing to making jigs, panels, or custom engravings without changing tools or setups.

Professional Grade, Reliable, and Versatile Manufacturing Station--Professional Grade, Reliable, and Versatile Manufacturing Station for 24/7 production, high‑precision prototypes, and end‑use parts, designed to handle a wide range of engineering materials while maintaining consistent quality, uptime, and workflow efficiency.

Exceptional Print Volume with Compact Design--The H2C offers a generous build area while still fitting comfortably on a standard workbench. This balance lets you tackle large parts or batch jobs without needing a huge industrial footprint.

59 Intelligent Sensors and AI Monitoring--Dozens of sensors continuously watch temperatures, motion, and extrusion so the machine can detect issues early. AI‑assisted checks before and during prints help prevent failures and protect your hardware and materials.

Ultra-fast 8-Second Induction Heating--Induction heating brings the hotend up to temperature in just a few seconds, reducing waiting time between filament or hotend changes. This means faster multi‑material prints and higher productivity on every project.

Fully Automated Nozzle Offset Calibration--The H2C automatically measures and calibrates nozzle offsets with high precision, so dual‑head alignment is always accurate. You avoid tedious manual tuning and get crisp color boundaries and perfect interfaces between different materials.

Revolutionary Vortek Nozzle Swapping System--The Vortek system parks and swaps entire hotends instead of purging filament, so material changes are cleaner and much faster. This drastically cuts waste and keeps multi‑material prints consistent even on long, complex jobs.

What's Included

| Item | H2C AMS Combo | H2C Laser Full Combo | Ultimate Set |

|---|---|---|---|

H2C |

✓ | - | - |

H2C Laser Edition |

- | ✓ | - |

Build Plate |

✓ | ✓ | - |

Spool Holder |

✓ | ✓ | - |

0.4 mm Induction Hotend |

4 | 4 | 3 |

0.2 mm Induction Hotend |

✓ | ✓ | - |

0.6 mm Induction Hotend |

✓ | ✓ | - |

0.4 mm Hardened Steel Hotend |

2 | 2 | - |

0.2 mm Stainless Steel Hotend |

- | - | ✓ |

0.6 mm Hardened Steel Hotend |

- | - | ✓ |

4‑in‑1 PTFE Adapter II |

✓ | ✓ | - |

Accessory Box |

✓ | ✓ | - |

AMS 2 Pro |

✓ | ✓ | ✓ |

AMS HT |

- | - | ✓ |

10W Laser Module |

- | depending on option | - |

40W Laser Module |

- | depending on option | - |

Cutting Module (with Pen holder) |

- | ✓ | - |

Laser Platform |

- | ✓ | - |

Cutting Platform |

- | ✓ | - |

Emergency Stop Button |

- | ✓ | - |

Which Bambu Lab 3D Printer Series Is Right For Me?

Technical Specifications

Vortek multi‑hotend system

The Future of Additive Manufacturing

Multi-Material. Multi-Color. Multi-Function.

Unmatched Precision Meets Versatility